Product overview

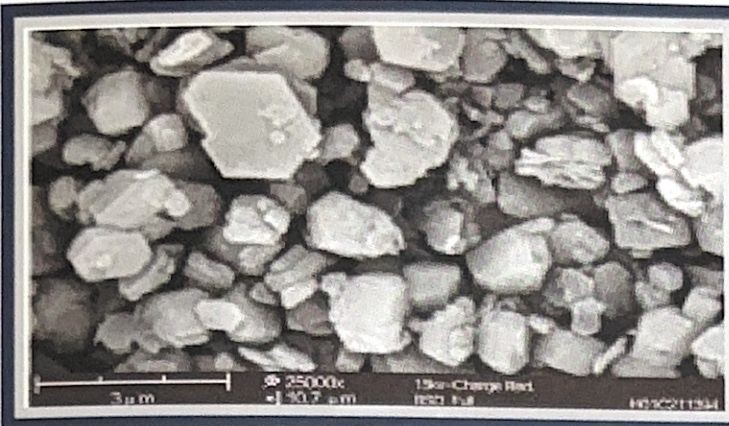

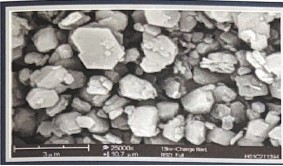

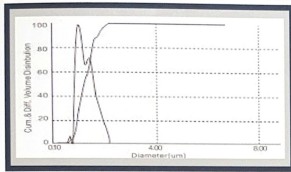

This product is a high purity sodium aluminate solution as raw material,by precipitation of ultrafine alumia hydroxide powder, with small particle size, good crystal shape, high whiteness, high chemical purity, narrow particle size distribution, low conductivity characteristics. As an environmentally friendly flame retardant filler. Micro-powder aluminum hydroxide is widely used in low-smoke halogen-free cable, silicone rubber, lithium battery diaphragm, foam insulation materials, paper fillers, thermoplastic PVC and so on.

Product characteristic advantage

Insulation layer and forcables.The substance of theprotective layer;And suitable for differ-ent voltages.

Used in thermoplastic PVC products,It acts as a flame retardant,It also inhibits the smoke.The effect of production.

Used for lithium battery separator Coating material, Play heat resistance, high temperature resistance, The role of insulation.

upgradable Resistance to leakage marking of silicone rubber And corrosion properties;

Good compatibility with whitening agent, good ink absorption,can improve the whiteness of coated paper, opacity,smoothness, ink absorption,can be used in thermal paper,painting newspaper,banknote paper, photo paper and advanced dictionary paper and other advanced paper production.

Used for insulation of foam materials,Provides fire resistance And consistent holesize.

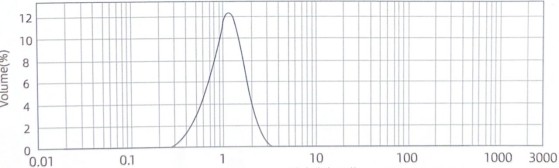

Particle size distribution figure

Flame retardant mechanism

Dehydration and heat absorption at 200-350°C Inhibition of polymer temperature rise.

Al(OH)3 after dehydration on the fuel surface

Generate Al2O3 protective film Cutting off oxygen prevents further combustion.

In rubber, plastic and resin, etc

After filling Al(OH)3 in organic polymer,The concentration of combustible substance in the composite material decreases;In addition,Al(OH)3 is released after thermal decomposition,Water vapor dilutes the concentration of combustible gases and oxygen, Can effectively slow down or prevent combustion.

Aluminum hydroxideflame retardant

Produced undercombustion condition.Strong dewatering Substance (transitionalumina),

Carbonize plastics Less likely to produce Flammable volatiles To stop the flames from spreading.

The main uses of the products

Product application characteristics

Product characteristic index